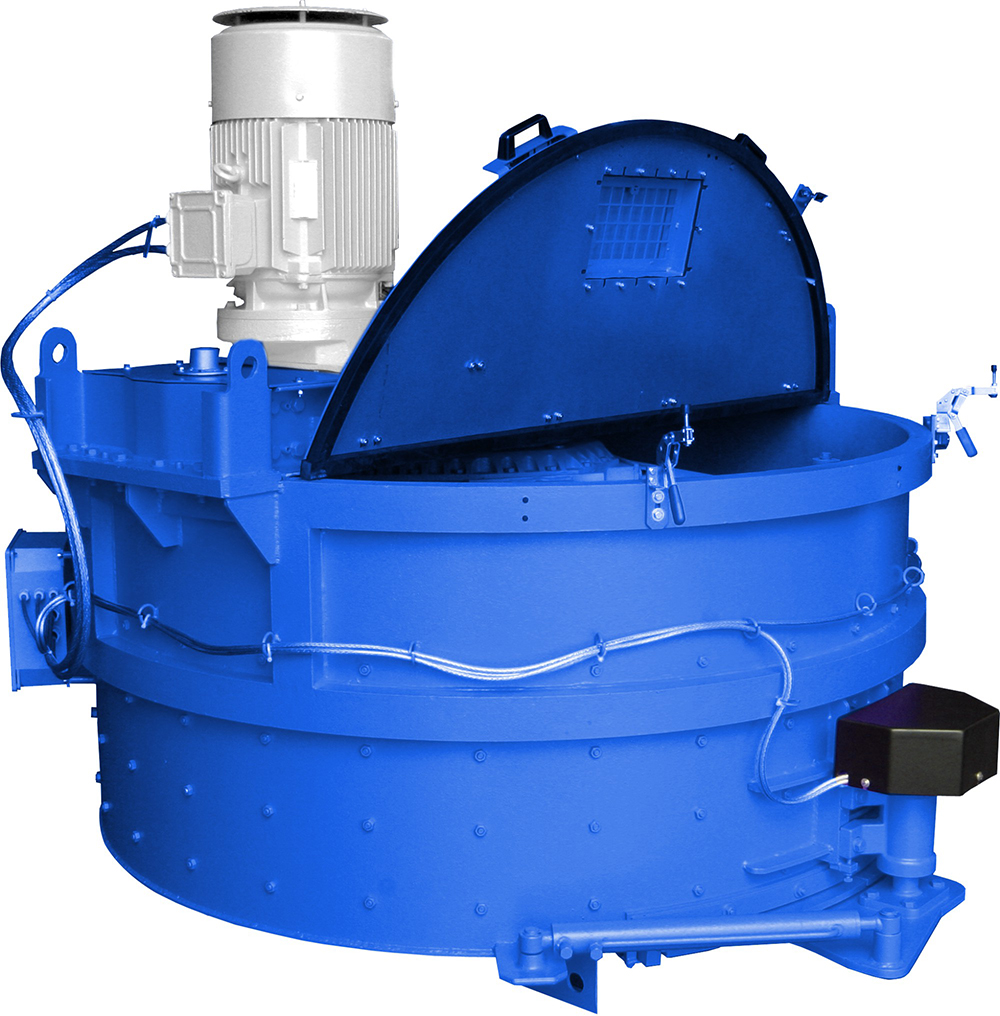

Planetary Mixer

Features

Quality System:

The Manufacturing Procedures used for all SICOMA Mixers have been compliant with the Quality Requirements of ISO 9001 since 1995 and have been updated and approved by CERMET since 2009 as compliant to ISO 9001:2008.

Mixing Arms

ICOMA’s mixing action starts with the arms, which are responsible for most of the mixing, from top to bottom. Three cast iron arms per star, two stars starting fromMP 1875/1250 and three stars for MP 4500/3000 and MP6000/4000. Together with two hardened steel scraping arms they are the best for toughness plus abrasion resistance. Adjustment slots allow easy blade adjustment to compensate for wear.

ICOMA’s mixing action starts with the arms, which are responsible for most of the mixing, from top to bottom. Three cast iron arms per star, two stars starting fromMP 1875/1250 and three stars for MP 4500/3000 and MP6000/4000. Together with two hardened steel scraping arms they are the best for toughness plus abrasion resistance. Adjustment slots allow easy blade adjustment to compensate for wear.

Mixing Blades

Complete the mixing action and give fast discharge. Cast from Ni-hard iron, 550 HB minimum, for extreme wear resistance. Outer edges are thickened to equalize wear and the angle of attack is optimized to push, not slice, to maximize both mixing and blade life.

Linear Plates

15 mm Ni-hard cast iron tiles give many times the life of abrasion resistant steel liner plates, reducing lifetime cost. Bolted assembly makes replacement a simple task; in addition, the wall plates are reversible to increase life even further. Additionally, tight fabrication tolerances mean that blades can be adjusted close to walls and floor for perfect clean out between batches, ensuring the best performance on coloured products.

Gear Box

Gear Box

With 70 years of mechanical experience, Sicoma has created a gearbox virtually indestructible. The huge double horizontal design is strong and shock resistant. The wide horizontal oil bath is cool running and gives every gear optimum lubrication. It is good for life and carries a 5 year, 10,000 hour warranty.

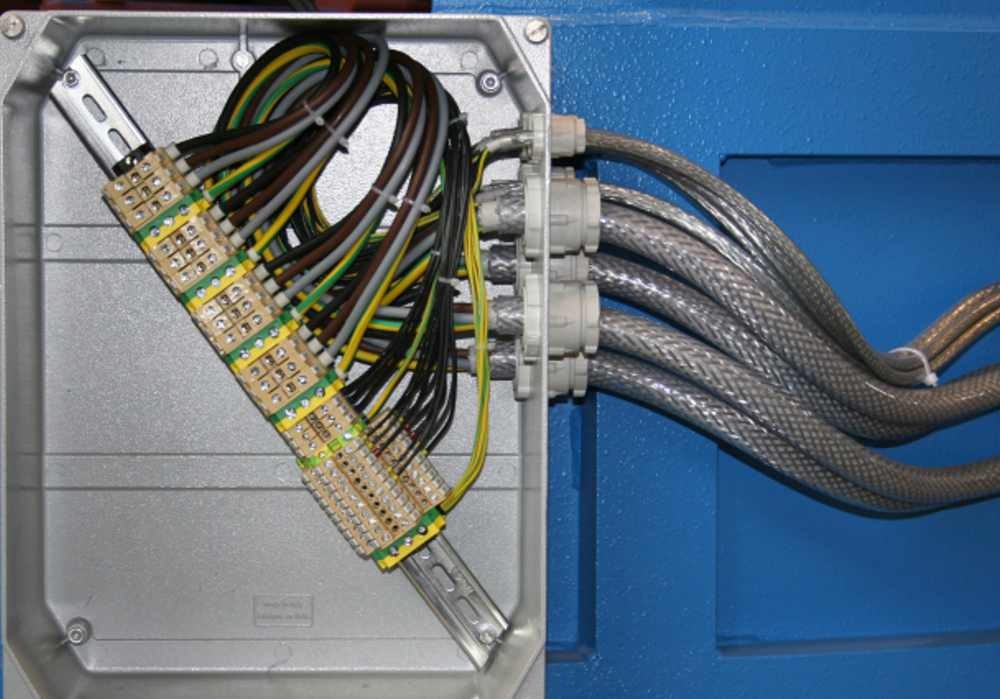

Junction Box

Junction Box

All connections, including motor 3-phase power as well as solenoid valves and switches, are available in one easy access junction box.

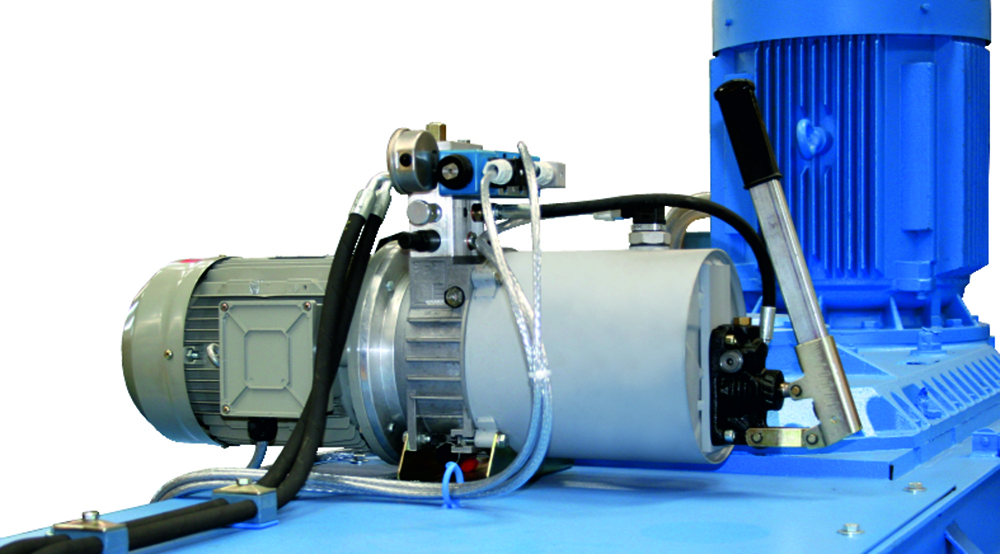

Hydraulic Power Pack

Hydraulic Power Pack

Providing plenty of capacity to operate doors reliably in even the largest mixer. Manual lever allows the door dual use, to be opened during power loss and to be closed right after.

Discharge

Up to four swing-out sector doors running in rubber seals are completely watertight, non-jamming and low in maintenance, further reducing lifetime cost. Larger models are hydraulically powered while small models have choice of pneumatic or manual operation.

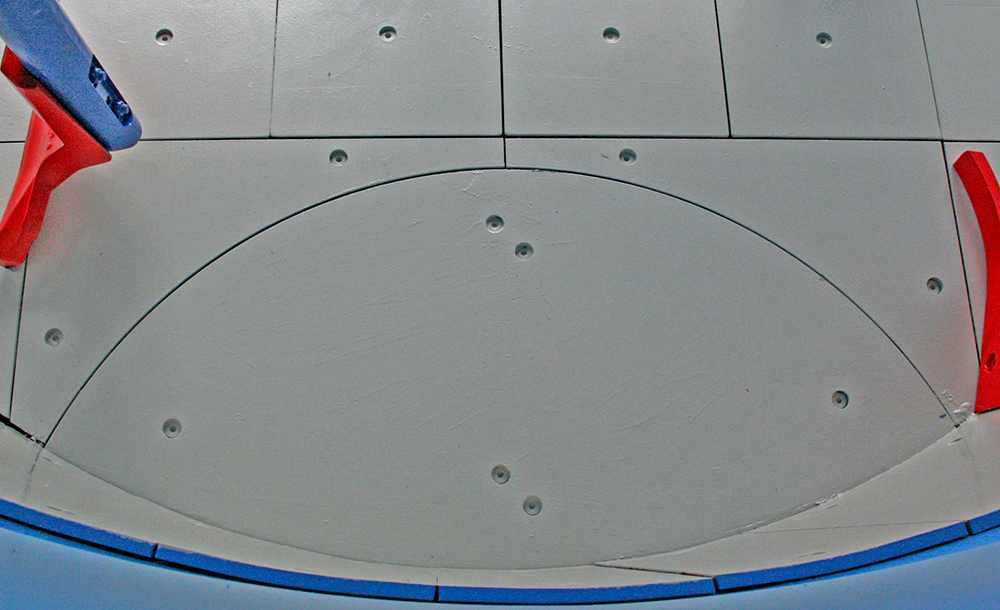

Half-Moon Cover

Half-Moon Cover

Widest opening of any, to give faster cleanup and adjustment of wear parts while making the process safer all round. One, two or three-part depending on mixer size. Single piece cover with hydraulic lift for easiest access is optional in largest models.