Brochures

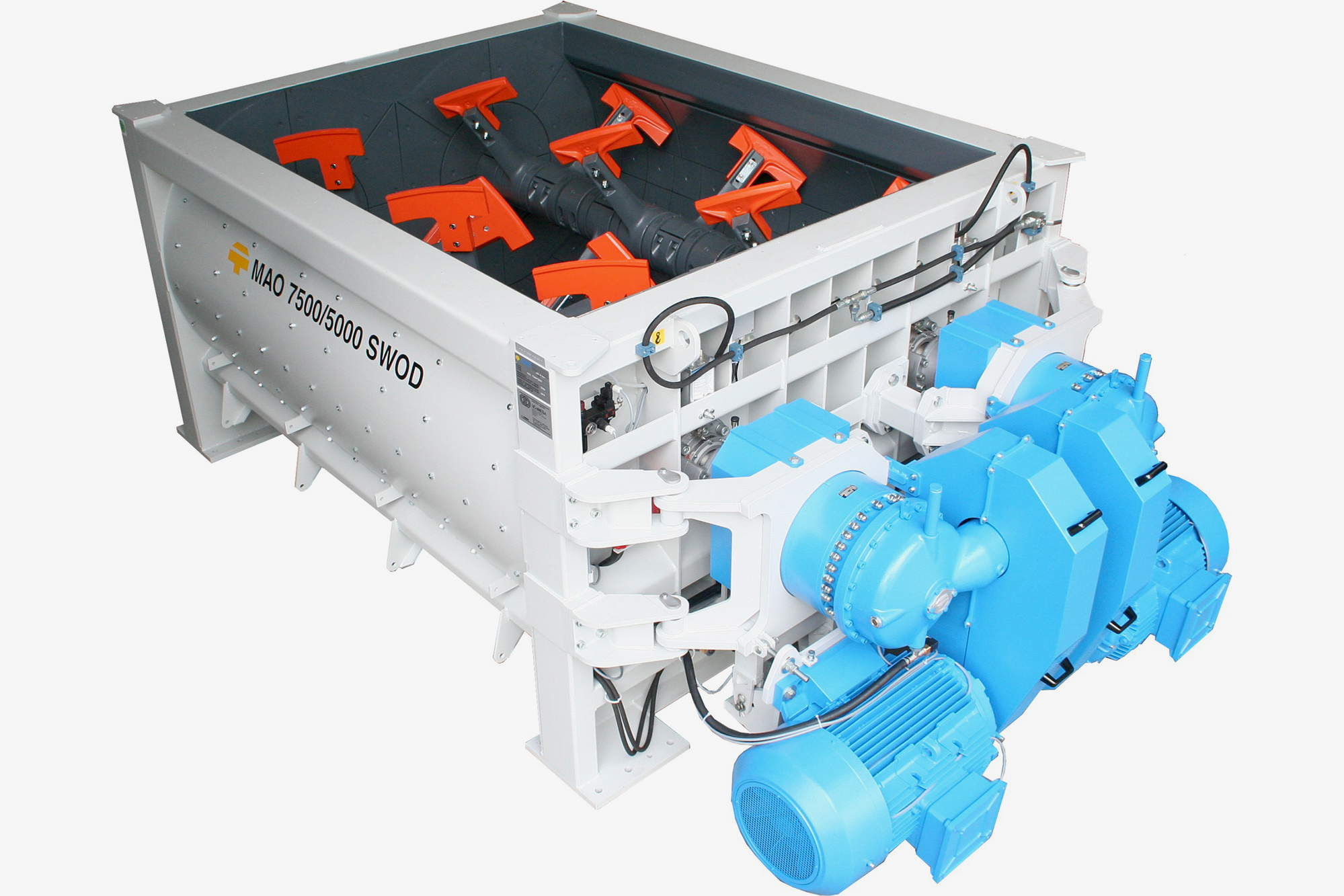

Twin Shaft Mixer

The Sicoma twin shaft concrete mixer was designed in Italy 16 years ago, and it has been refined to give you the outstanding product that you see today. The MAO series heavy duty mixers are the most widely used twin shaft models in the world today; over 6000 in use, worldwide, in ready-mix, precast, block, paver and dam applications.

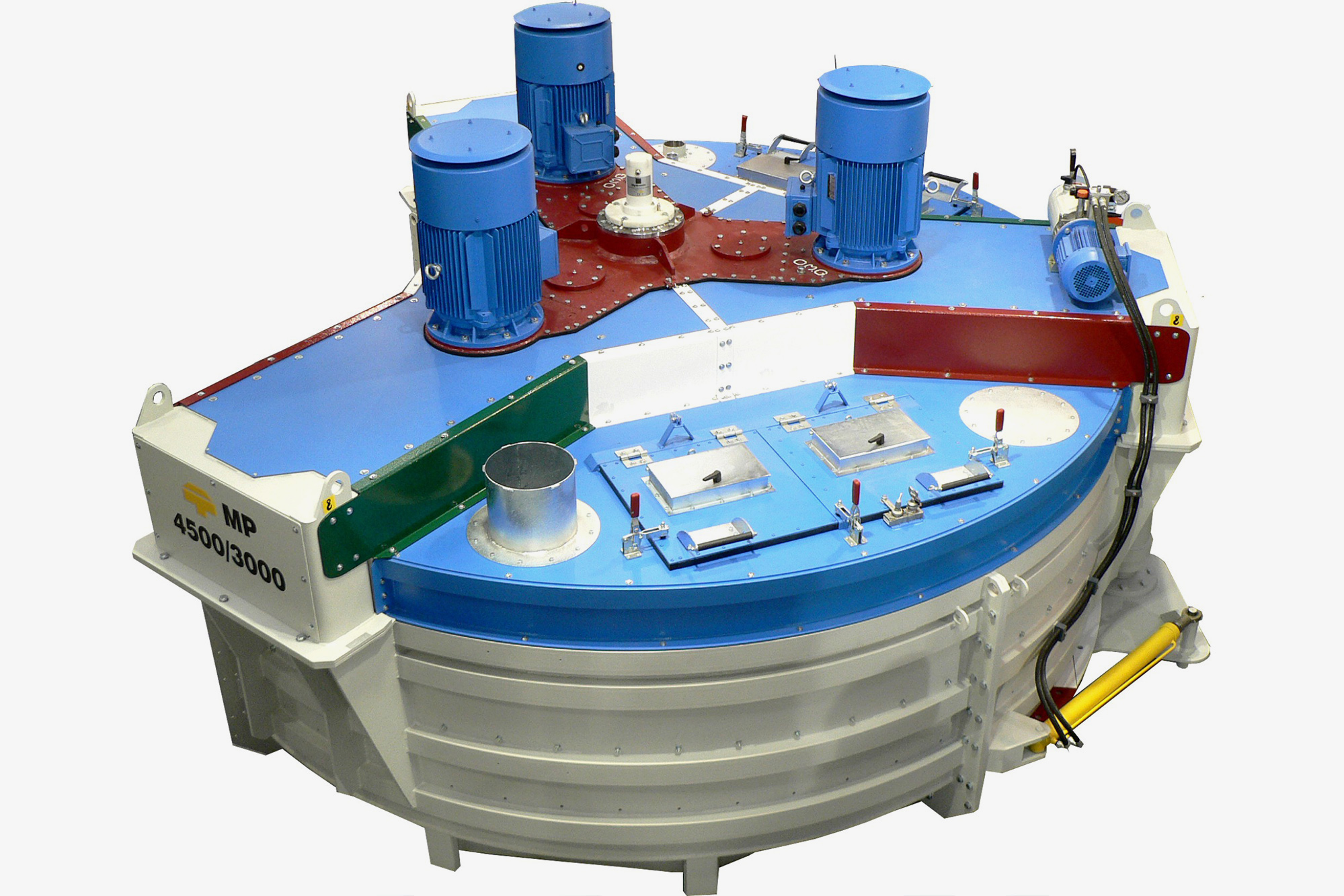

Planetary Mixer

The Sicoma high speed planetary / countercurrent concrete mixer the best in its class. From its beginnings as an uncompromising basic design it has been continuously refined over many years, so that today's product contains the little touches that you expeThere are more than 8000 Sicoma high speed planetary / countercurrent concrete mixers in use today around the world.

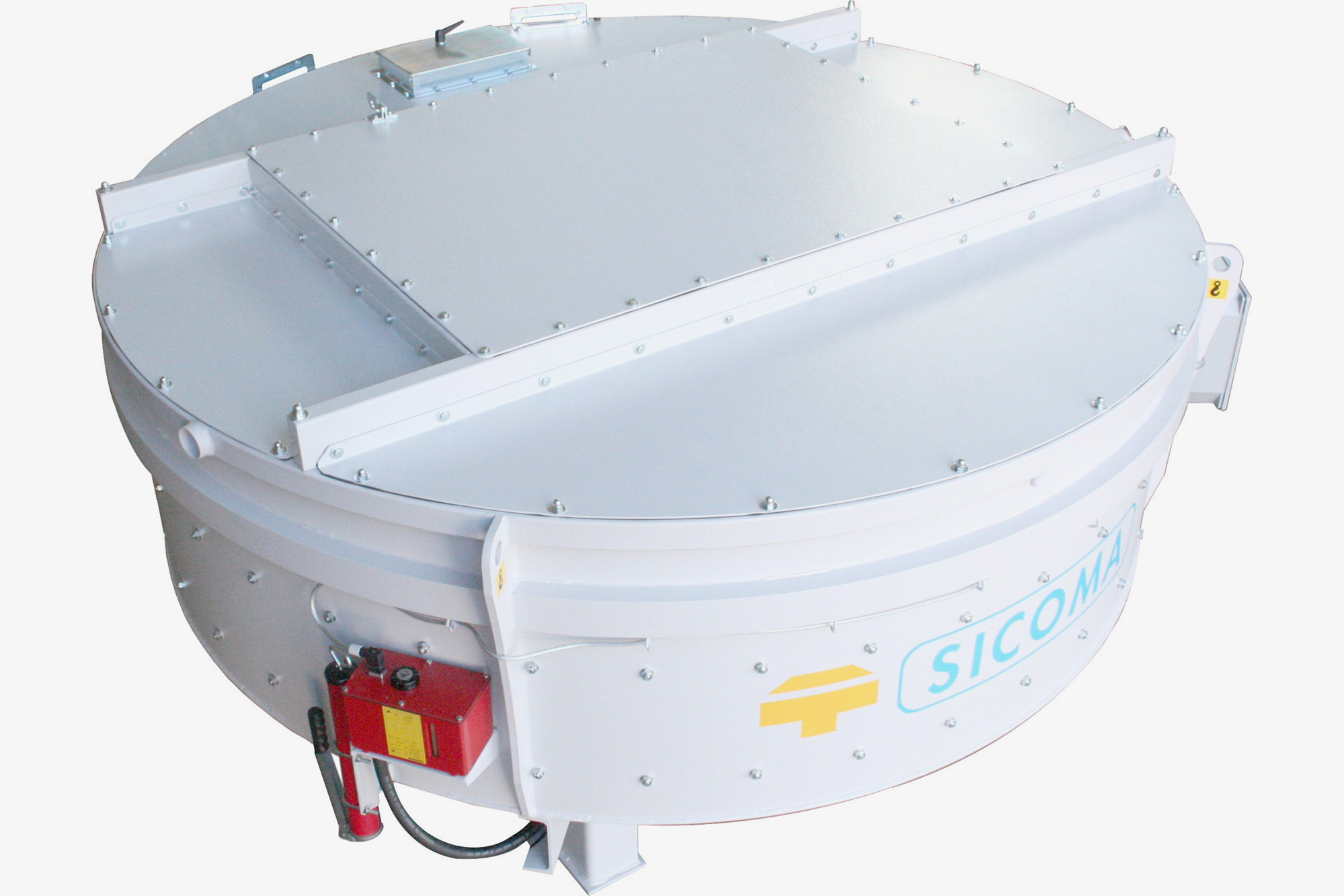

Lab Mixer

To meet the need for lab testing of new mix designs and for training in technical centres and universities, the Model MP75 is the elite of the industry. It is a fully functional planetary mixer with all the extra features normally required for application: raise/lower control for mixer top and mixing gear, tipping pan and electric heaters to control mix temperature.

Concrete Distribution Systems

Electromechanical motion Travelling Bucket with Double Clamshell Gate operated by hydraulic power pack, with On Board Control System.

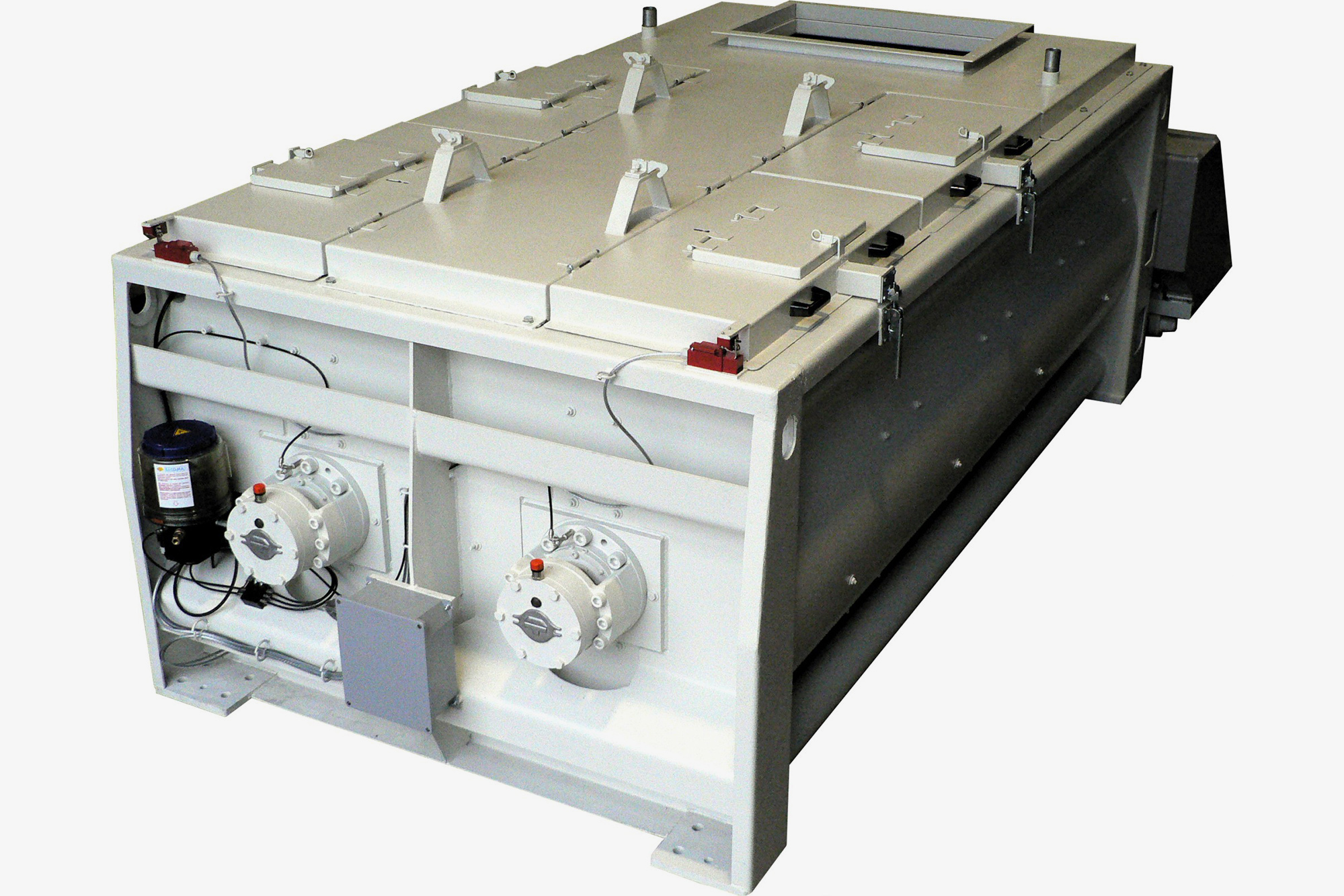

Twin shaft Continuous Mixer

he continuous (or 'pug mill') mixer model MAO/C gives a stream of mixed concrete based on volumetric proportioning. Material is fed into one end from two or more aggregate conveyors, cement screw feeder and flow-metered water.