Turbo Pan Mixer

Features

MIXING TANK

All Sicoma Turbine mixers can be shipped in standard open top containers or trucks due to the fact that the tank can be separated into two or more bolted segments. Re assembly on site is simple and quick as the segments are located on positioning pins and then bolted together. The tank walls and floor are lined in wear resistant steel plates. Under request, they can be lined with Ni-Hard plates.

All Sicoma Turbine mixers can be shipped in standard open top containers or trucks due to the fact that the tank can be separated into two or more bolted segments. Re assembly on site is simple and quick as the segments are located on positioning pins and then bolted together. The tank walls and floor are lined in wear resistant steel plates. Under request, they can be lined with Ni-Hard plates.

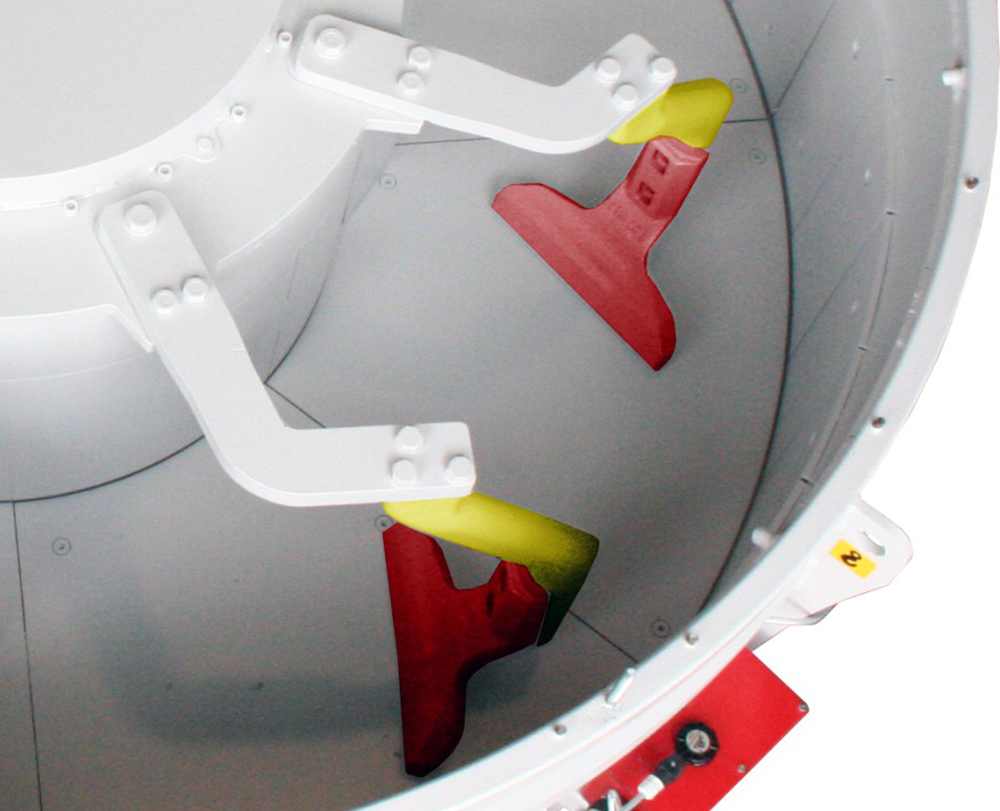

MIXING ARM SPRING SYSTEM

MIXING ARM SPRING SYSTEM

All the mixing arms are connected to the rotating drive system with spring shock absorbers operated by cams. This system absorbs any shock loads caused by the mix blades hitting obstructions and protects the drive gearbox. It also allows easy adjustment of the mix blades clearance to the tank floor.

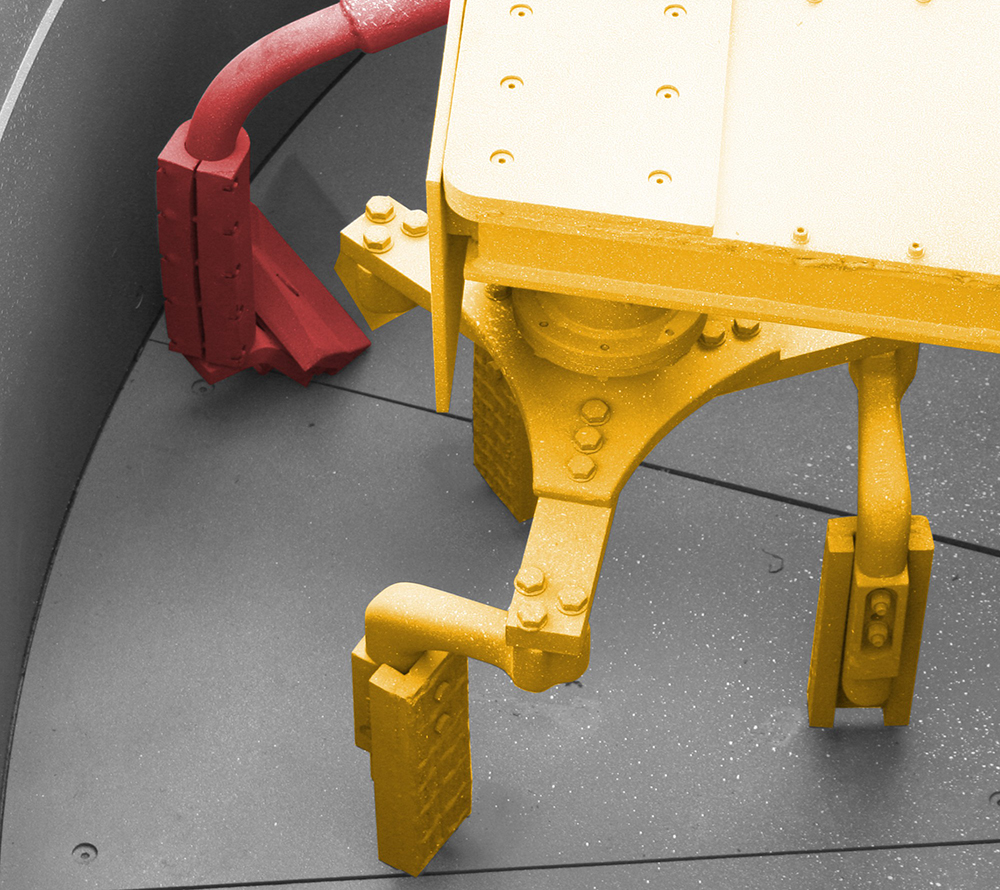

AGITATOR AND DISCHARGE ACCELERATOR SYSTEM

AGITATOR AND DISCHARGE ACCELERATOR SYSTEM

SICOMA Turbine mixers can be fitted with one or twin rotating agitator systems to increase mixing efficiency and to reduce the mix cycle time. A special discharge blade can further reduce the total mixing cycle time.

DISCHARGE DOOR

All parts of the discharge door/s are produced using very accurate CNC machining and the full door assembly is then bolted to the tank. This guarantees the correct positioning of the door and that the door segment rotates in a perfect arc and is in contact with the rubber door seal on the tank. This prevents any unwanted leakage when the door is closed and prevents any possibility of the door jamming.

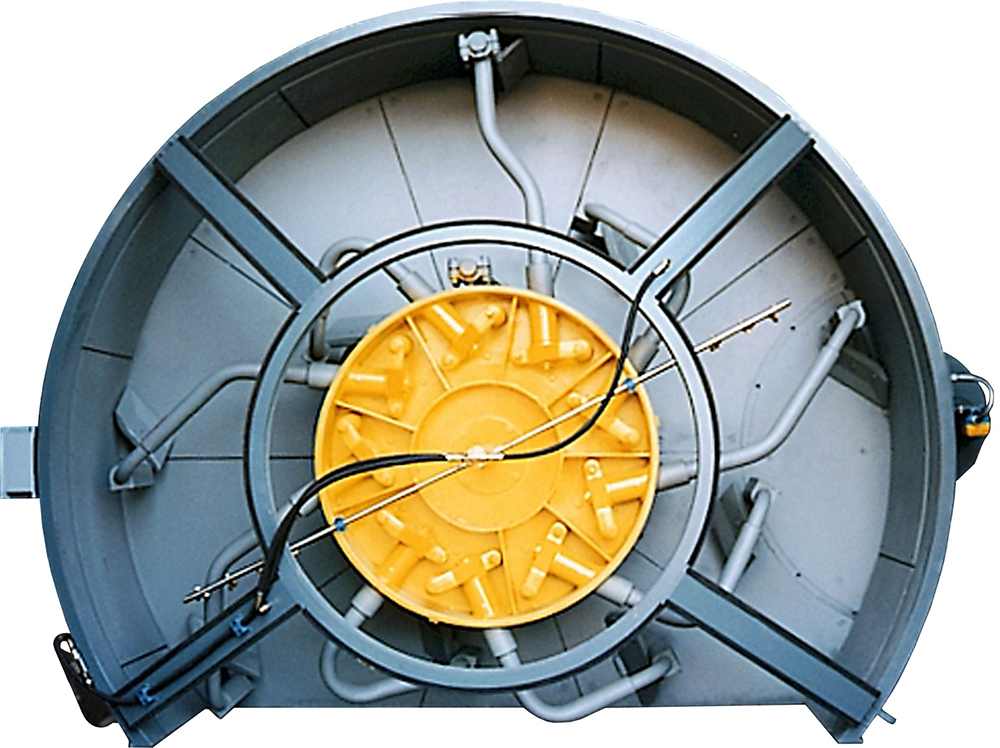

HIGH PRESSURE WASHOUT

Two high pressure rotating stainless steel spray bars with adjustable spray nozzles fixed to the drive turret wash the mixer floor very thoroughly and a further two fixed bars wash the arms and mixing paddles as they rotate, as well as the pan walls.

ACCESSORIES

All Sicoma turbine mixers have a range of optional accessories available, these include aggregate skip hoists, cement weigh hoppers, water weighing systems, dust reducing airbags, high pressure wash systems, accelerated discharge blades and multiple discharge doors. All accessories are pre-assembled in the factory to guarantee minimum assembly time on site.